Manufacturer of Technical Adhesive Tapes

3F is a high-performance developer and manufacturer of technical adhesive tapes for a wide range of applications. Every year, we coat and convert millions of square meters of self-adhesive materials and supply numerous industries at home and abroad. Since our founding, we have enjoyed healthy, continuous growth and are the first point of contact for a large number of customers in all aspects of adhesive bonding technology.

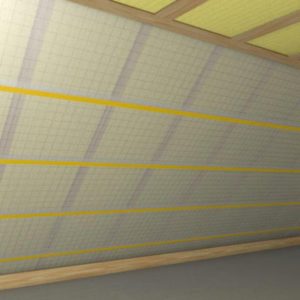

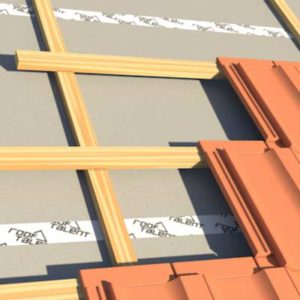

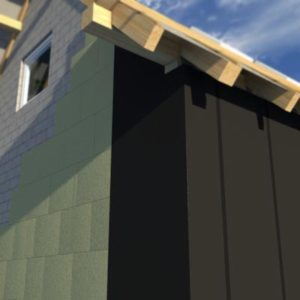

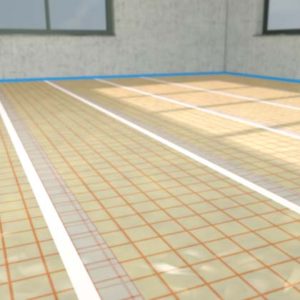

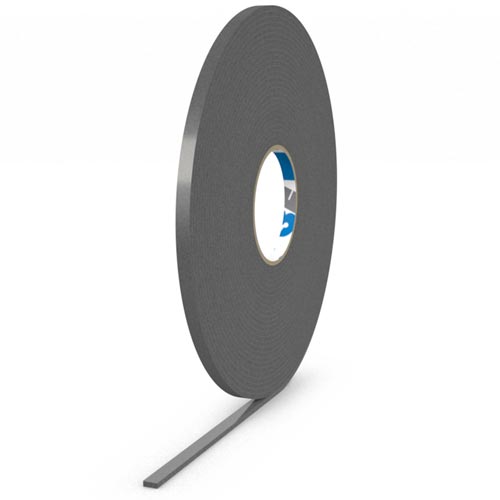

Our products include Transfer Tapes and Double-sided Adhesive Tapes with different carrier materials, Foam Tapes made of different types of foam, Single-sided Adhesive Tapes sometimes for the construction industry, and Adhesive Coatings in Contract Manufacturing on, for example, nonwovens or films. 3F adhesive tapes and coatings can be found in all industries, so our adhesive tape solutions are meanwhile used in all major branches.

Our customers include industrial companies that process adhesive tapes or use them as an aid in manufacturing processes, trading companies that make our finished products available to commercial and private end users, or adhesive tape converters that purchase semi-finished products from us and process them into ready-to-sell cut rolls.

Tape Variety

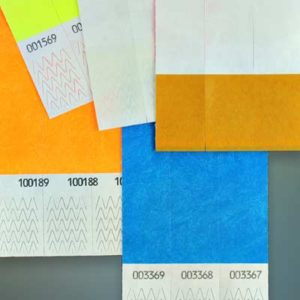

The 3F product portfolio includes, on the one hand, a range of proven and frequently used standard adhesive tapes. Their application possibilities are very versatile, so that the most diverse customer groups fall back on them.

On the other hand, our diversity of raw materials in the areas of adhesives, carrier materials, intermediate carriers and release liners enables us to offer an almost limitless, modular product system that allows us to respond perfectly to special areas of application and customer requirements.

Furthermore, we offer specific adhesive tape recommendations for many industries, which have proven their functions in many years of practical tests and have established themselves as qualified industrial solutions.

Tape Development

In addition to the production of adhesive tapes, their development is an important focus of our service areas. Our specialist Research & Development department is continuously working on new adhesives and industrial solutions for various industries.

We also carry out product developments for special areas of application as part of joint, constructive projects in cooperation with our customers and merge the know-how of various specialist areas into progressive innovations.

Tape Manufacturing

The modern machinery of our adhesive tape production includes several coating lines. They all have different strengths and capacities, so that all types of products can be manufactured to the respective ideal conditions.

Our coating lines are complemented by various adhesive tape converting machines on which we produce cut rolls, long rolls, cross-wound spools and other roll formats.

The wide range of our production facilities ensures a great deal of flexibility in manufacturing and enables us to respond individually to our customers’ needs in every respect.

Industries we serve:

Automotive & Transport

Household & Electronics

Industry & Commerce

Construction

Health & Hygiene

Energy

News

Company

3F boosts employee satisfaction through new partnership with Corporate Benefits

At the end of September, 3F GmbH announced its new partnership with Corporate Benefits to [...]

Oct

Company

3F at Foam Expo 2022 in Stuttgart, Germany

From 08 to 10 November 2022, we will be exhibiting at Foam Expo Europe in [...]

Oct

Worth knowing:

What is the structure of an adhesive tape?

Adhesive tape is the term used to describe single- and double-sided self-adhesive strips or webs that are available to the user in various roll formats. Depending on the type of tape, in addition to the adhesive they also contain carriers and intermediate carriers as well as release liners that cover the adhesive.

The uses of adhesive tapes are extremely diverse and can include applications such as mounting, packaging, surface protection, sealing, insulation, soundproofing, process aid or repair. The many areas of application also account for the large number of adhesive tape types, which can differ greatly in terms of structure, raw materials and performance.

What are the functions of the various adhesive tape components and which variants are available?

The adhesive plays a major role in determining the quality of an adhesive tape, because its properties must match the intended use. Parameters such as adhesive strength, internal strength, processing temperature, temperature resistance, compatibility with the surfaces to be bonded and other characteristics are decisive. So the more precisely the requirements for an adhesive are defined, the better we as an adhesive tape manufacturer can determine the ideal adhesive for your projects.

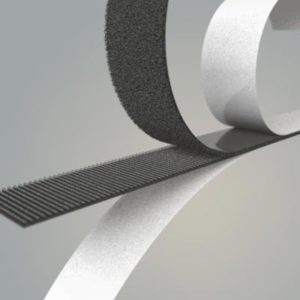

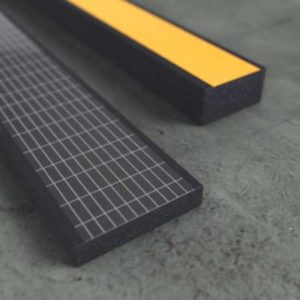

The carrier material of an adhesive tape carries the adhesive, but also has a functional task. Because the many carrier materials with their different properties give the adhesive tape character and function. Ultimately, the application determines whether film, foam or fabric is used as a carrier, for example. Intermediate carriers are also frequently incorporated, for example a thread scrim embedded in the adhesive.

Release liners end up as a waste product, but they play a crucial role in the processing of the tape. They are usually made of foil or paper and cover the adhesive layer. They are usually coated with a release agent such as silicone so that they cannot form a permanent bond with the adhesive. The release liner makes roll winding possible and with its help the user of the tape can control when the adhesive film should be exposed.

What are your tape needs?

Do you need adhesive tape solutions for special applications? Are you looking for a reliable, qualified adhesive tape supplier?

Contact us – we will be happy to advise you on all aspects of adhesive bonding technology.