60000//

EPDM foam tape, one-sided self-adhesive

Product features:

- Foam carriers made of EPDM (ethylene-propylene-diene rubber) in various thicknesses

- Standard coating with acrylic adhesive, good initial and final adhesion

- Release liner with silicone coating

- Ideal as sealing tape for outdoor applications, good resistance to aging, UV radiation, weathering and temperature

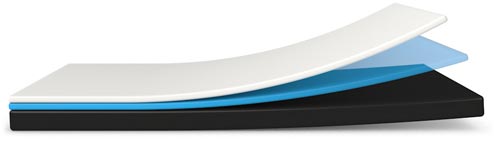

Product structure:

Release Liner | Paper, white

Adhesive | Polyacrylate

Foam | EPDM, black

70000//

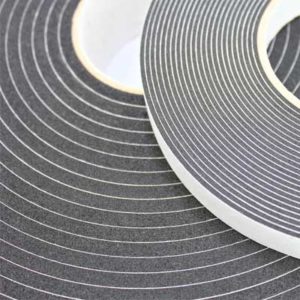

CR foam tape, one-sided self-adhesive

Product features:

- Foam carrier made of CR (chloroprene rubber) in various thicknesses

- Standard coating with acrylic adhesive, good initial and final adhesion

- Release liner with silicone coating

- Ideal as sealing tape for outdoor applications, high resistance to aging, UV radiation, chemicals, weathering and temperature

Product structure:

Release Liner | Paper, white

Adhesive | Polyacrylate

Foam | CR, black

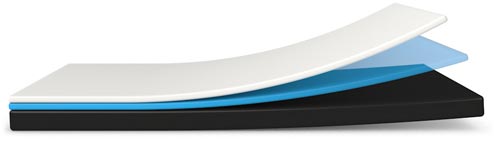

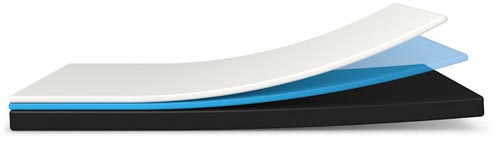

50000//

Natural rubber foam tape, one-sided self-adhesive

Product features:

- Foam carriers made of natural rubber in various thicknesses

- Standard coating with acrylic adhesive, good initial and final adhesion

- Release liner with silicone coating

- Ideal as sealing tape for interior use, good ageing resistance

Product structure:

Release Liner | Paper, white

Adhesive | Polyacrylate

Foam | Natural rubber, black

EPDM Tape

EPDM is a synthetic rubber with high resistance to heat and other weather conditions. As an adhesive tape there are therefore many areas of application in outdoor areas.

The anchorage of adhesives on the closed-cell foam surface is high, so that a very good final adhesion on different substrates can be guaranteed.

Common applications of EPDM adhesive tapes are profiles, seals or EPDM sheets with adhesive strips. Due to the variable EPDM thickness and the possibility to use adhesives with different properties, the products can be adapted exactly to the intended use.

Besides EPDM, CR and natural rubber adhesive tapes are also available. CR (chloroprene rubber) has an extended resistance to various chemicals and is considered the highest quality cellular rubber. Natural rubber, on the other hand, fulfils only normal requirements in terms of temperature and ageing, but is the most cost-effective option.